薄片研磨 その1.機械摺り

Most impotant part of thin-section making process.

The process is recemble to tip grinding, but some details are different.

This stage is the most important stage in the whole process to make good thin-sections!

At First: The machinery stage:

最初に機械を用いた摺り

Second Stage:The hand stage is the next page->

2番めの手による研磨は次のページ

#180 Grinding; until the section turns transparent around 0.1-0.3mm thickness,

#180 の摺り:薄片の厚さが 0.1-0.3mmで岩石が透明になるまで摺る.

Next Video, a Gabbro section,

次の動画ははんれい岩の薄片

The section color changes lighter.

The thickness: 2.35mm to 1,48mm at 2min. Average rate is 0.44mm/min

薄片の色がしだいに薄くなる.上記ビデオでは2分間で 2.35mm から 1,48mm に減っている.1分で0.44mm減った勘定になる.

Another video, an Andesite section,

別の動画で安山岩の薄片

This video shows a little bit thick section about 3.81mm(-1.3mm = 2.5mm is the actual thickness of rock)

The thickness decrease 2.5mm to 0.3-0.4mm during 2.5 min.

So, the grinding rate is around 0.9mm/min.

This rate is the mean value from my experiences.

これはかなり厚い薄片.石の厚さが2.5mmほどある.2分半で 2.5mm が 0.3-0.4mm まで減った.

この減り方は私の経験から言ってほぼ平均の値.

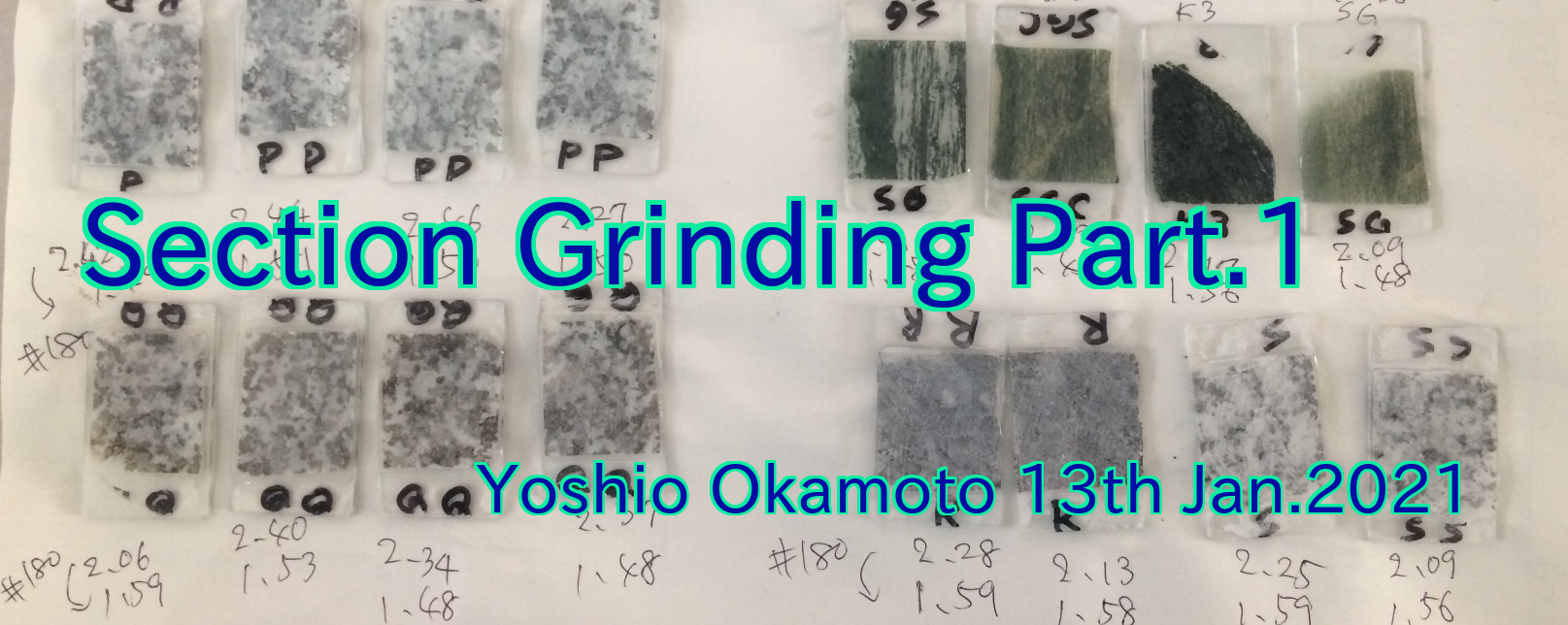

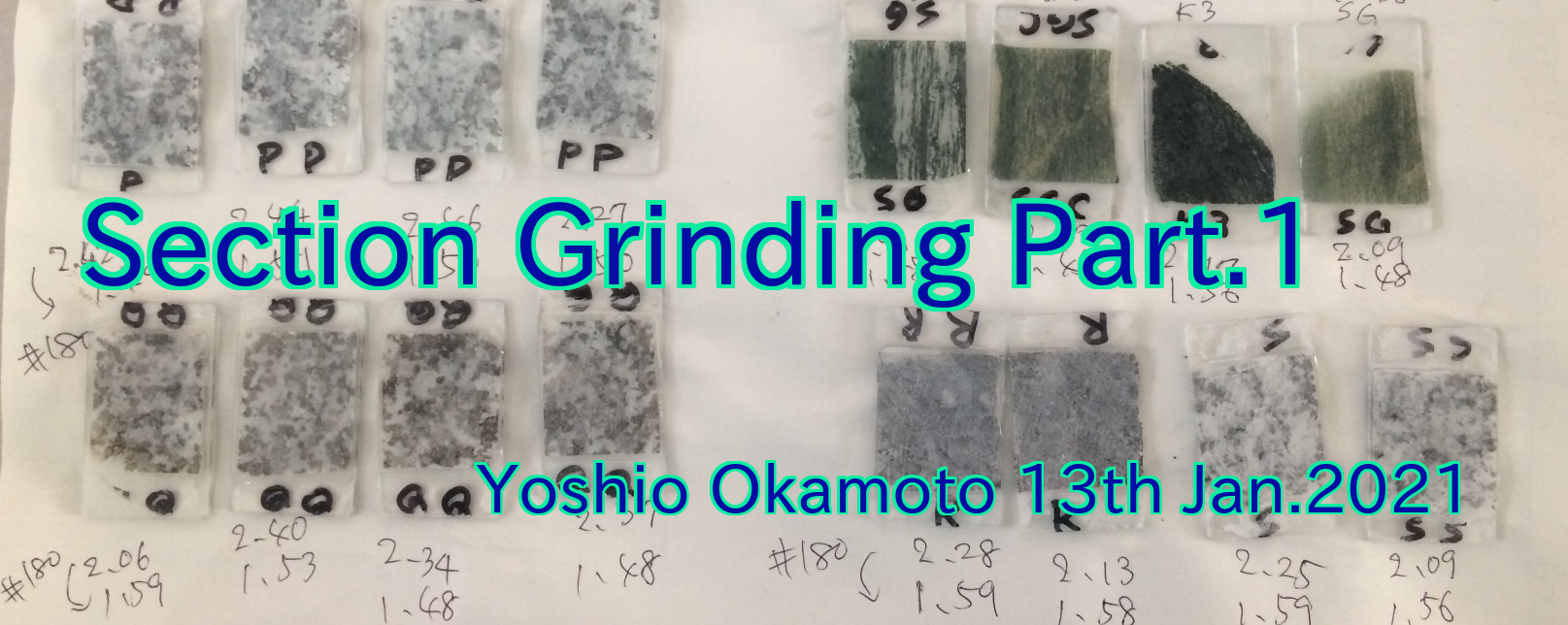

The image shows the difference between before and after #180 grinding.

この写真は#180の前とあとでの違いを示す.

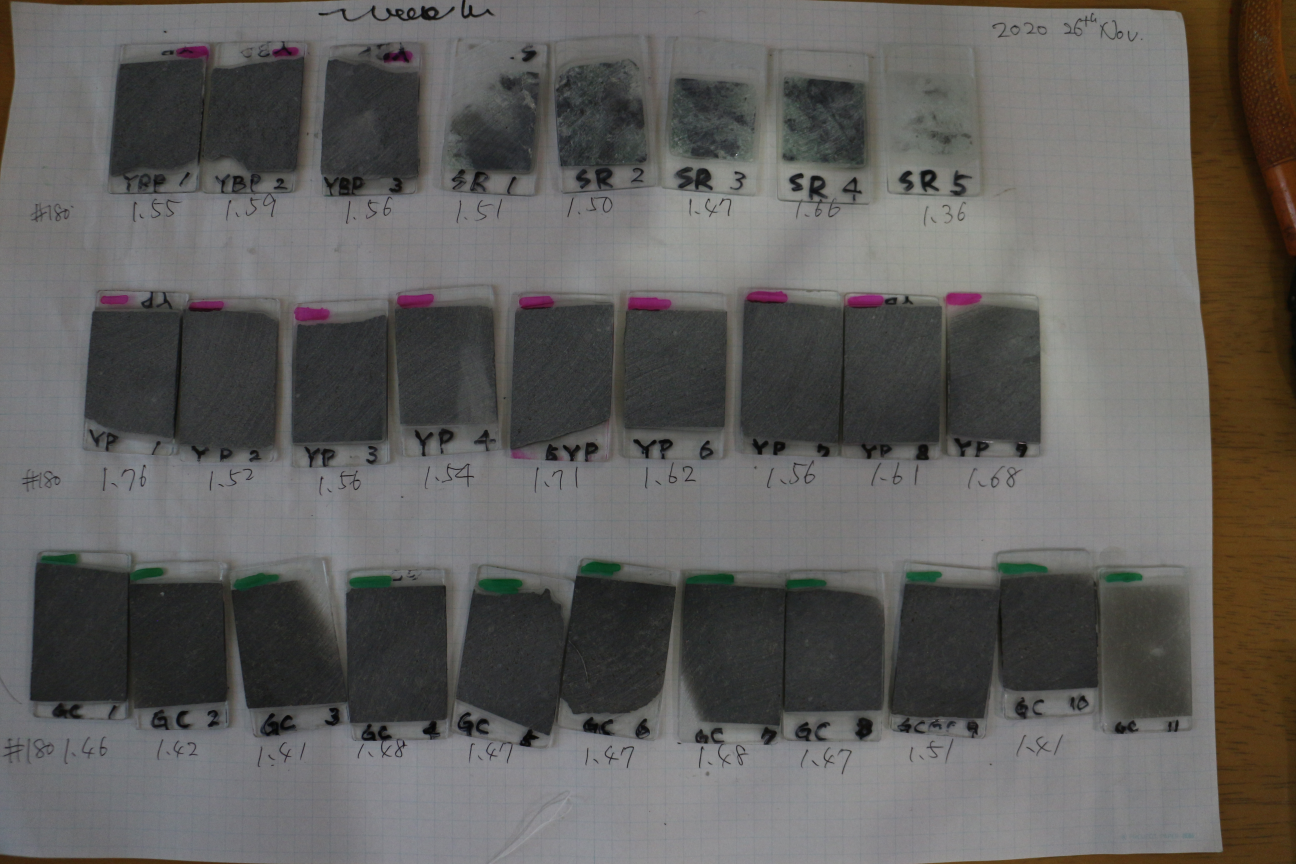

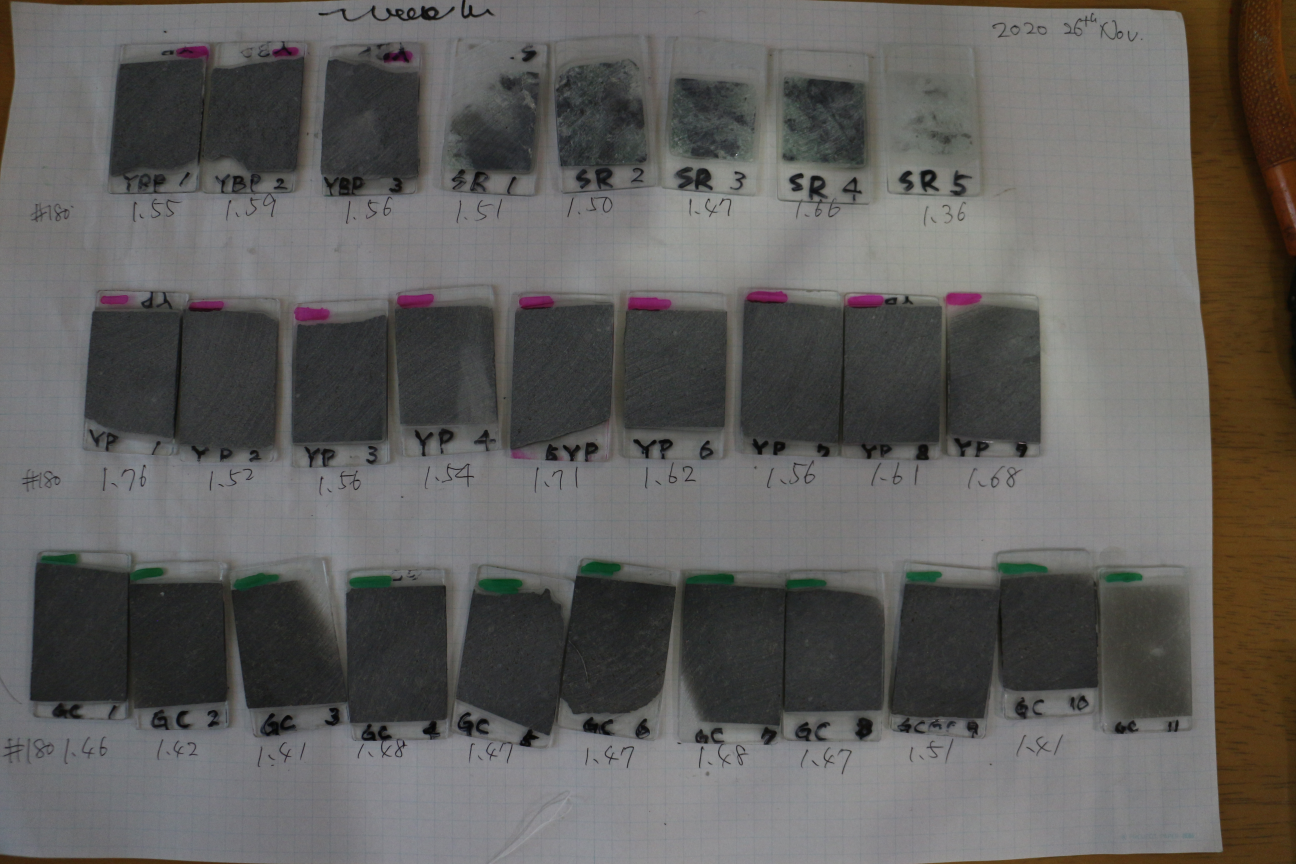

After #180, Kannabe Basalts, numbers

are thickness of sections (glass thickness are 1,27-1,29mm) :the

thicknesses are measured by a digital caliper. Samples are basalts at Kitatajima

これは#180のあとの状態で,写真の数字はそれぞれの薄片の厚み(1,27-1,29mm厚のガラスを含む)を示す.なお厚みは上の写真のデジタルゲージで測定.サンプルは北但馬の玄武岩.

Next;

#320 Grinding

次は#320の摺り.

This video shows: thickness 1.5mm reduces to 1.33mm (actually 0.2mm to 0.03mm) during 1.5min.

It means the grinding rate is 0.11mm/min. The #320 has a mild grinding rate than #180.

Also, You can see the color of section turns to transparently.

この動画は1分半の時間で,1.5mm の薄片が 1.33mm に減っている (石本体の厚みは 0.2mm が 0.03mmに減る).

Another example, Diorite,

他の例として閃緑岩

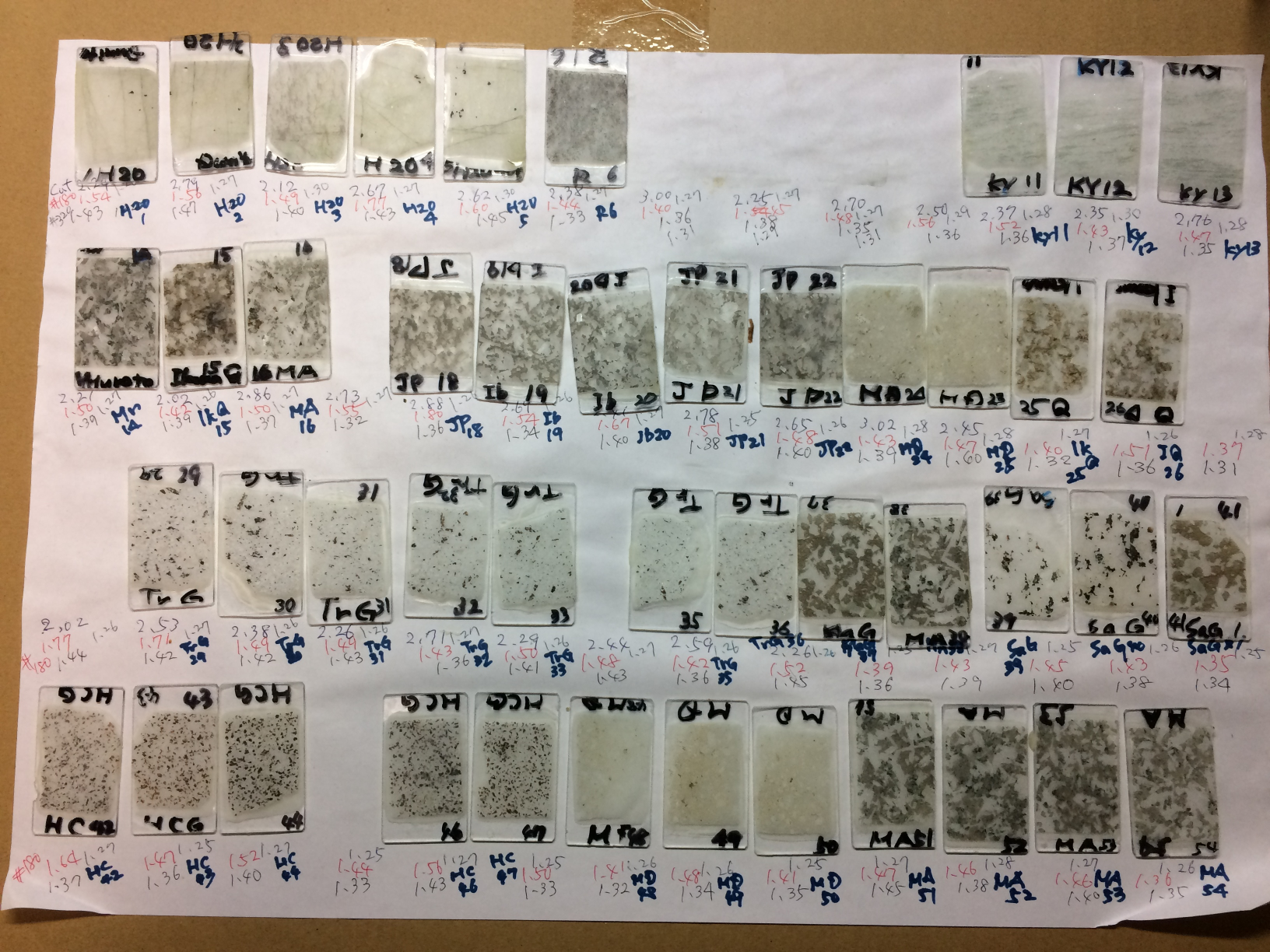

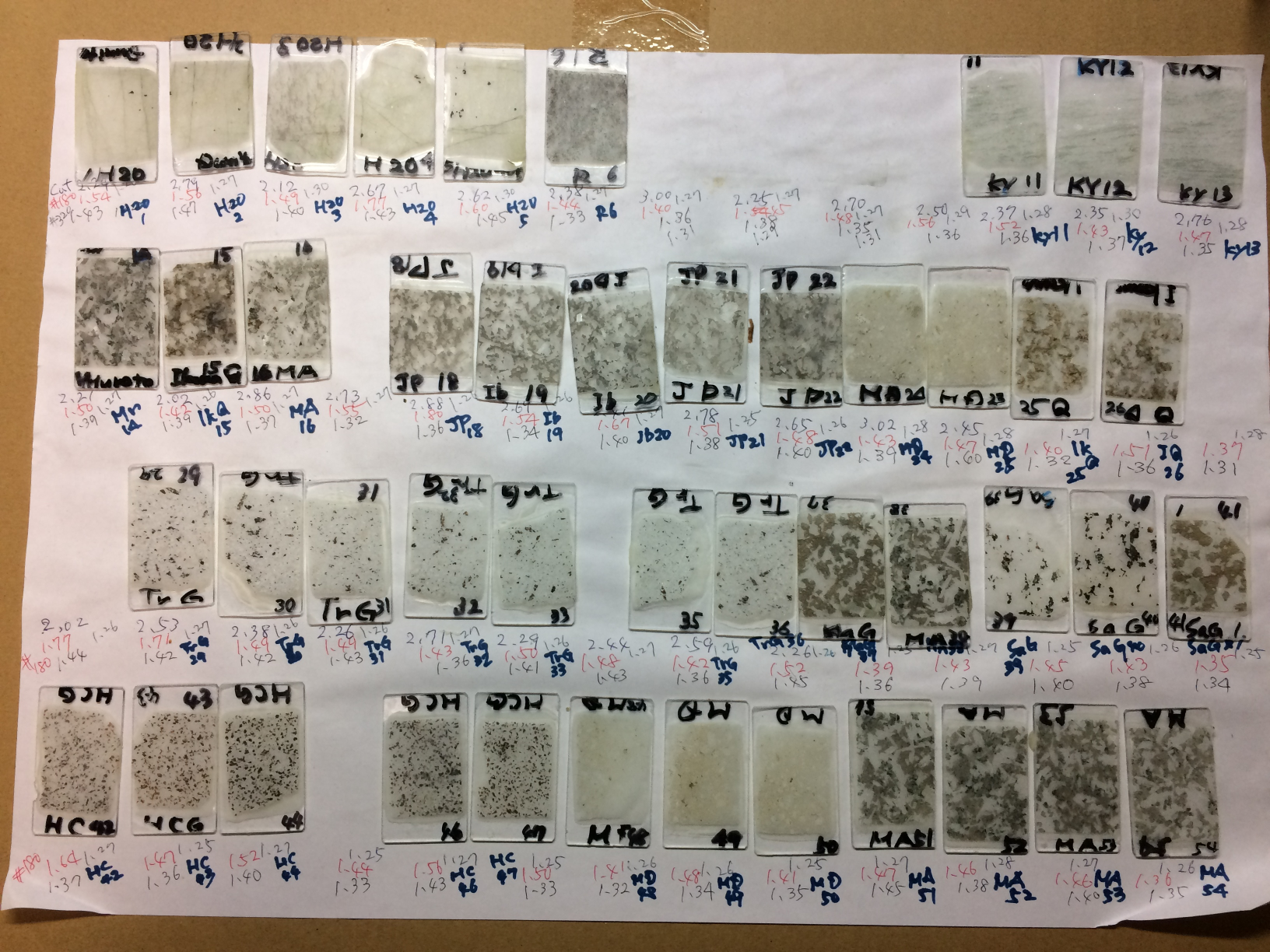

After finishing with homemade Grinder #180 to #320

The numbers show after section-cutting, #180 and #320, descending

order. measuring with a digital caliper including glass and glue.

Next Stage -->

Copyright(c) by Y.Okamoto 2021, All rights reserved.