自作岩石切断機によるチップの切断

Prepatation:

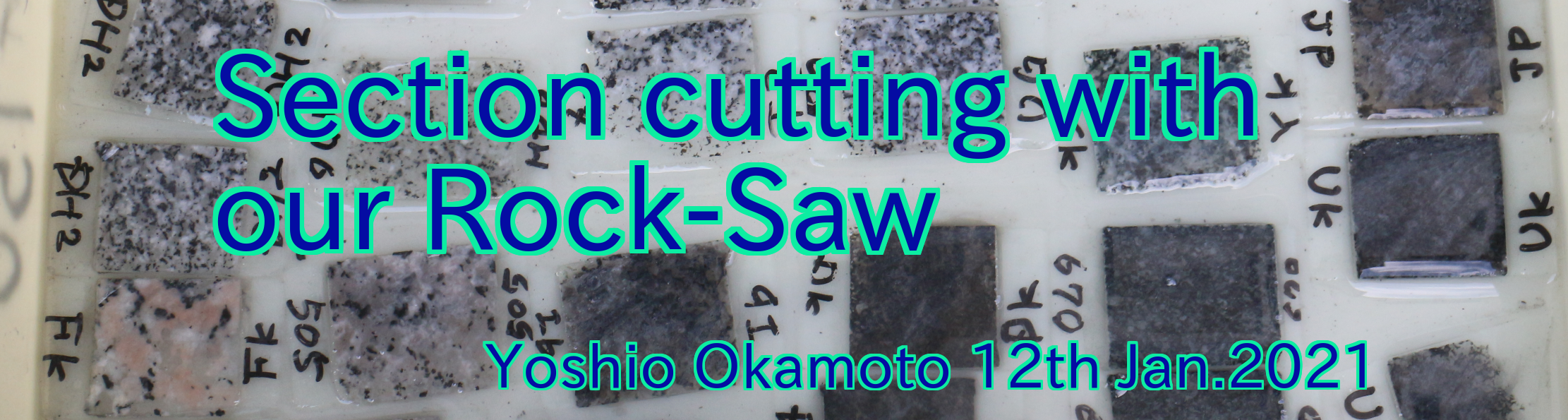

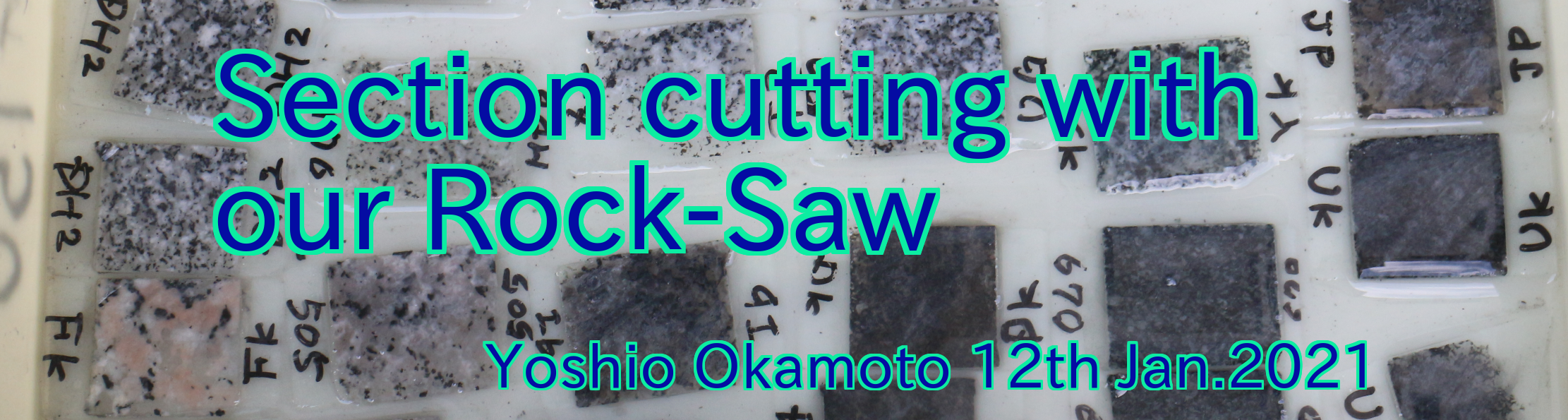

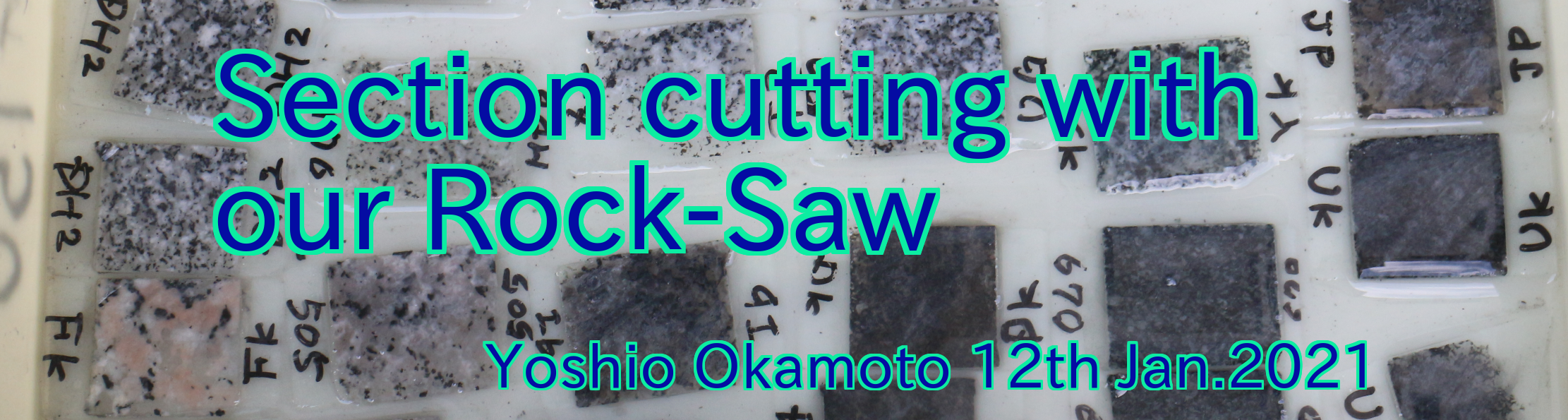

Tips glued on the slide glass, we call them sections, These samples are collected at Mt.Higashiakaishi ultramafics and schists.

準備:

スライドガラスに貼り付けたチップ,東赤石山の超塩基性岩と結晶片岩.

Preparation for Rock-Saw

岩石切断機の準備

Preset a cutting guide (an acrylic plate) for section sawing.

切断のための治具を取り付ける.

Please check the following video

Cutting a section slowly along the cutting guide like this,

In this process; You have to cut the section thinner as you can to handle the next grinding stage efficiently.

But, please take care not to cut the slide glass!

この過程では,できるだけ薄くセクションを切る方が,次の摺りのステージで楽ができる.ただしあまり薄く切るとスライドグラスまで切ってしまう!

Finished sections; mainly ultramafic and metamorphic rocks at Mt.Higashiakaishi and Sekigawa in Shikoku.

切断を終えたセクション.主に東赤石山と関川の超塩基性岩と変成岩.

An example of cutting tips thickness after cutting, The numbers are

thickness of tips + glass in mm, the glass thicknesses are around

1.27-1.30mm.

So, most of the actual tip thickness lay between 0.5 to 1.2mm. Of

course, thinner tips are better for the next grinding stage. The samples

are basalts and volcanic tuffs in Kyusyu.

切断を終えた薄片の厚みの例.このときのスライドガラスの厚みは1.27-1.30mmである.

したがって,薄片の真の厚みは大体,0.5 to 1.2mmとなる.当然ながら薄いほど次の研磨ステージには有利である.サンプルは九州(阿蘇周辺&開聞岳)の玄武岩と凝灰岩類.